Synchronous belt combines the advantages of timing belt drive, chain drive and gear drive. When the timing belt rotates, the power is transferred by engaging the belt tooth with the tooth groove of the pulley. It has accurate synchronous drive function, without slip difference, no pollution and little noise. Drive efficiency reaches to 0.98. Speed ratio range can fulfill 1:10. Allowable linear speed can attain 50m/s. Drive efficiency ranges from several hundreds watts to several kilowatts. It's suits multi-axial drive. Therefore, it can work good in places where pollution is not allowed and the working environment is relatively harsh.

Features

● Accurate transmission, no slip, with a constant transmission ratio.

● Easy maintenance, no need of lubrication, low maintenance cost.

● Can be used for long distance transmission, center distance up to more than 10m .

● Compared with V-belt transmission, the preload is smaller, and the load on the shaft and bearing is smaller

● High efficiency due to positive engagement between the Belt teeth and pulley grooves

Specification

SYNCHRONOUS BELT | |||||

Section | Pitch (mm) | Tooth Height (mm) | Thickness (mm) | Model Range | |

Min | Max | ||||

2M | 2.00 | 0.75 | 1.36 | 488 | 506 |

3M | 3.00 | 1.17 | 2.40 | 111 | 3000 |

5M | 5.00 | 2.06 | 3.80 | 175 | 3770 |

8M | 8.00 | 3.48 | 6.00 | 112 | 4400 |

14M | 14.00 | 6.02 | 10.00 | 826 | 4578 |

20M | 20 | 8.40 | 13.20 | 2200 | 4200 |

S2M | 2.00 | 0.76 | 1.36 | 120 | 3000 |

S3M | 3.00 | 1.14 | 2.20 | 102 | 3210 |

S5M | 5.00 | 1.91 | 3.40 | 160 | 2765 |

S8M | 8.00 | 3.05 | 5.30 | 376 | 4400 |

S14M | 14.00 | 5.30 | 10.20 | 966 | 3850 |

MXL | 2.032 | 0.51 | 1.14 | B50 | B1463 |

XXL | 3.175 | 0.76 | 1.52 | B156 | B158 |

XL | 5.080 | 1.27 | 2.30 | 54 | 828 |

L | 9.525 | 1.91 | 3.60 | 98 | 1676 |

H | 12.700 | 2.29 | 4.30 | 60 | 2100 |

XH | 22.225 | 6.35 | 11.20 | 463 | 1750 |

XXH | 31.750 | 9.53 | 15.70 | 1000 | 1600 |

Applications

Paper and textile machinery, CNC machines, printers, scanners, office machines, Robotic machines, electric hand tools, currency counting machines, food processing machines, Machine tools, computer, printers, sewing machines, oil pumps, etc.

Production Details

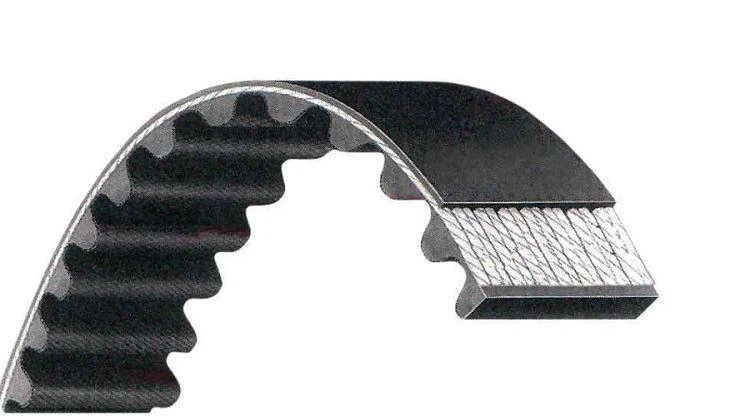

① Superior polychloroprene backing

② Superior Fibre-glass cord

③ High modulus Fibre loaded polychloroprene rubber compound

④ Nylon 66 stretch fabric teeth for high wear resistance

Installation

① When installing the synchronous belt, if the center distance of the two belt wheels can be moved, the center distance of the belt wheels must be shortened first, and then the center distance shall be reset after the synchronization belt is installed. If there is a tensioning wheel, first loosen the tensioning wheel, then install the synchronous belt, then install the tensioning wheel.

② When install the belt to pulley, remember not to force too much, or with a screwdriver forced pry synchronous belt, in order to prevent the tensile layer in the belt produced invisible appearance of breaking phenomenon. When designing the pulley, it is better to choose the structure that the two axes can move close to each other. If the structure does not allowed, it is better to install the synchronous belt and the pulley on the corresponding shaft.

③ In the synchronous belt drive, the parallelism of the axis of the two belts have high requirement, otherwise the synchronous belt will run off-track or even jump out of the pulley during working. Non-parallel axis will also cause uneven pressure, so that the tooth wear early.