Automotive timing belt also called engine timing belt, it's mainly used for OHC drive, applying to the condition of various speed range and high temperature transmission conditions. Rubber timing belts made from HNBR can withstand a wide range of temperatures and still maintain flexibility. It has greater advantages than chain drive.

Features

● Low noise level & longer service life

● Strong transmission capacity

● High grade HNBR rubber for superior heat and contamination resistance.

● Aramid reinforced nylon jackets and backsides increase durability and lifetime.

● Wide Range of Load Capacities and Speeds

Specification

TIMING BELT | |||

Section | Pitch (mm) | Tooth Height (mm) | Belt Height (mm) |

ZA | 9.525 | 1.91 | 4.10 |

ZB | 9.525 | 2.92 | 4.5 |

ZH | 9.525 | 3.50 | 5.50 |

YH | 8.00 | 3.04 | 5.20 |

ZR | 9.525 | 3.20 | 5.7 |

YS | 8.00 | 3.04 | 5.2 |

ZS | 9.525 | 3.53 | 5.7 |

YA | 8.00 | 2.95 | 5.2 |

ZAS | 9.525 | 2.32 | 4.62 |

ZBS | 9.525 | 2.76 | 5.06 |

S8M | 8.00 | 3.05 | 5.30 |

YU | 8.00 | 3.02 | 5.20 |

FS | 9.525 | 3.05 | 5.35 |

MY | 8.00 | 3.06 | 5.20 |

MR | 9.525 | 3.54 | 5.69 |

RU | 9.525 | 3.41 | 5.40 |

Applications

Automotive engines-exhaust & inlet valves

Production Details

① Superior HNBR backing

② Superior Fibre-glass cord

③ High modulus Fibre loaded HNBR rubber compound

④ Nylon 66 stretch fabric teeth for high wear resistance

Timing Belt Failure Analysis

1. Heat Degradation

Appearance: Cracking from high temperature operation, rubber

Cause

When rubber belts operate at elevated temperatures (greater than 185°F) for prolonged periods of time, the rubber compound gradually hardens resulting in back cracking due to bending.

These cracks typically remain parallel to the belt teeth and usually occur over land areas (in between belt teeth), as illustrated in picture. Belts generally fail due to tooth shear, which often leads to tensile cord fracture.

Solutions

To determine if a special high-temperature belt construction will improve the belt performance in specific applications, contact a Pioneer Representative.

2. Foreign Objects

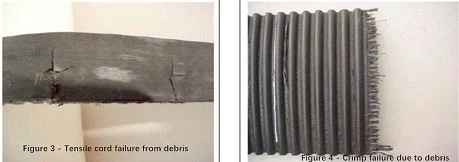

Appearance: Tensile cord failure from debris

Cause

The introduction of foreign objects between a belt and sprocket often damages both belt teeth and tensile cords.

Tensile cords often fracture internally (see Figure 3) or fail later due to crimping, as shown in Figure 4. Once a portion of the tensile cords have fractured, the remaining tensile strength of the belt has been reduced considerably.

Solutions

If belt damage from debris is noticeable, the belt should be replaced and the sprockets checked for damage. Damaged sprockets should also be replaced.